c. Origami-based Deployable Structure for 3D Volumetric Applications

Space Structure

Research

Research

Space Structure

Space Structure

c. Origami-based Deployable Structure for 3D Volumetric Applications

c. Origami-based Deployable Structure for 3D Volumetric Applications

c. Origami-based Deployable Structure for 3D Volumetric Applications

Principal Investigator: Jae-Hung Han

Participated Graduate Research Assistant: Jong-Eun Suh, Tae Hyeun Kim, Geon-IK Jang

Related Projects: NRF

Summary:

- The space structure group in SSHS Lab is conducting research to provide novel and efficient solutions for the issues on space structures: inflatable/deployable design, dynamics of the space structures, and vibration suppression in space structures. Regarding the inflatable/deployable system, we’ve tried to develop novel designs of the deployable system which have high packaging efficiency while ensuring reliable deployment. The concepts have been proved by the lab-scale prototypes.

Related Recent Publication:

- [1] Suh, J.-E., Miyazawa, Y., Yang, J., and Han, J.-H., “Self-Reconfiguring and Stiffening Origami Tube,” Advanced Engineering Materials, Online published, Mar. 2022.

- [2] Suh, J.-E., Kim, T.-H., and Han, J.-H., “New Approach to Folding a Thin-Walled Yoshimura Patterned Cylinder,” AIAA Journal of Spacecraft and Rockets, Vol. 58, No. 2, pp. 516-530, Mar. 2021.

- [3] Suh, J.-E., Kim, T.-H., and Han, J.-H., “New Folding Concept on the Cylindrical Structure with Yoshimura Pattern: Folding pattern analysis,” AIAA SciTech Forum 2020, Orlando, Florida, USA, Jan. 7-10, 2020.

Origami-based reconfigurable structures

1.Goals

- Development of the reconfigurable structure concept which achieves the load-bearing capability and safe reconfiguration at the same time.

- Demonstrate the proposed concept with the prototype to prove the feasibility of the application to the related field.

2. Approaches

Geometrical analysis on the Yoshimura-patterned tube

Simplified mathematical modeling via the truss-hinge framework

FEM static analysis

Prototype fabrication with handy materials

3. Recent Achievements

- Proposal of a novel reconfigurable cylinder concept based on Yoshimura-patterned tube, which originally reported as not suitable for the deployable/reconfigurable concept.

- Mathematical identification & classification of a complete set of the reconfigured configurations through the “path-finding” approach.

- The proposed concept ensures both load-bearing capability (at the Yoshimura configuration) and the reconfiguration at the same time.

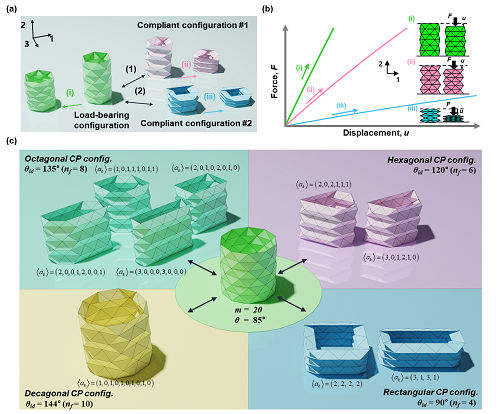

Fig. 1 Proposed concept of the reconfigurable structure based on Yoshimura-patterned tube: (a) Reconfiguration between Load-bearing configuration (i.e., Yoshimura-patterned tube) and compliant configuration (i.e., reconfigured configurations), (b) Different axial stiffness in each configuration, (c) The possible compliant configuration from a single design of Yoshimura-patterned tube

- The proposed reconfigurable tube has numerous feasible configurations within a single design; each of them shows different axial stiffness.

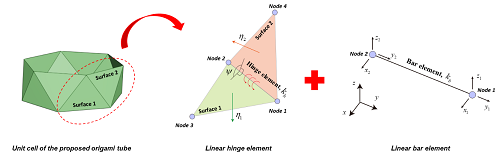

- Simplified mathematical model is established based on the truss-hinge framework

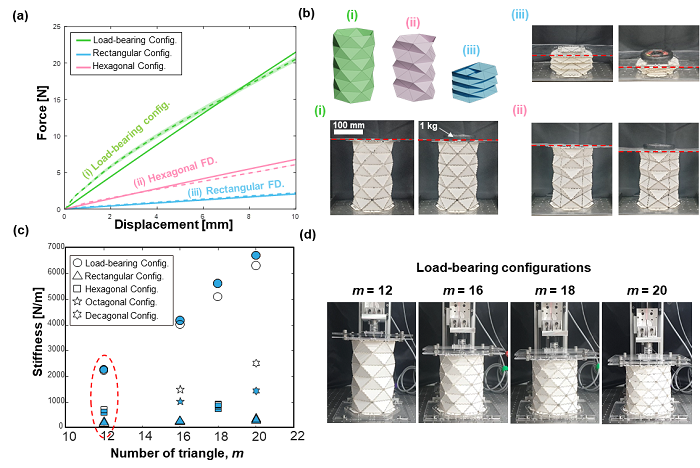

- Difference of the axial stiffness in the proposed reconfigurable origami tube is revealed according to their configuration.

Fig. 2 Schematics of the simplified mathematical model of the proposed reconfigurable tube: combination of bar and hinge element

Fig. 3 Results of static analysis and compression test: (a) Force-displacement curve for three configurations in a single design (solid line: numerical analysis results, dashed line: experiment result), (b) Digital images of the three configurations subjected to the analysis, (c) The stiffness of the reconfigurable tube with respect to the type of the configuration, (d) Digital images of four different times of the load-bearing configuration.

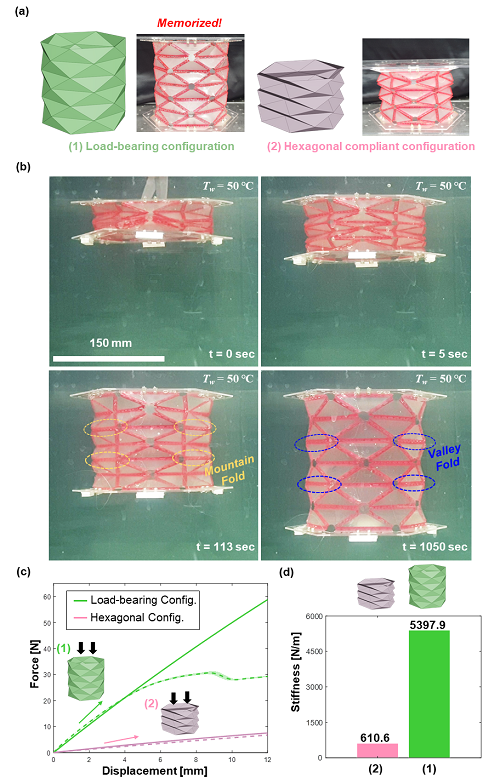

- The self-deployable and stiffening structure is designed based on the proposed reconfigurable origami tube concept.

- The prototype of the self-deployable and stiffening structure is fabricated by using shape memory polymer

Fig. 4 The self-deployable and -stiffening structure made of shape memory polymer: (a) Load-bearing configuration (left) and compliant configuration (right), (b) Self-deployment demonstration (c) Force-displacement curve of the structure (solid line: numerical analysis result, dashed line: experiment results), (d) The axial stiffness of the structure in each configuration